These recycle systems are designed to remove free hydrocarbons and filter water to be sent back through a pressure washer. They feature pH and ORP injection and are designed with corrosion-resistance tanks.

Features:

·Quality recycled wash water without common odor problems

·Easy operation and maintenance

·Poly skid is constructed of hardened polymer to be non-corrosive and can also be easily lifted and moved with a forklift

·Easily accessible pumps

·ETL listed control panel

Certification:

·ETL Certified – US and Canada

Recommended Applications:

·Rental Yards

·Heavy Equipment Dealers

·Trucking Facilities

·Military Bases

·Truck Rental Fleets

·Diesel Repair Facilities

·Forklift Washing Operations

·Aircraft Maintenance and Restoration

·Shipyards

·Municipalities/State DOTs

·Oil Fields

·Engine Rebuilders and Manufacturers

Models Available:

WLP-20-0M10 – 230V, 1Ø, 25.0A; 400 sq. ft. cartridge filter

WLP-20AB-0M11* – 230V, 1Ø, 25.0A

WLP-20AB-0M31* – 230V, 3Ø, 13.0A

*Auto-backwash models (air required 60 to 100-PSI)

230V/208V/460V 3Ø available on all models as options

The Importance of a Proper Pit System:

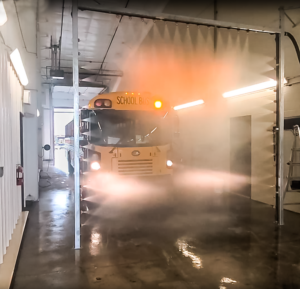

Once equipment is washed, the untreated wash water flows into your pit system. A proper pit system for your application is the first step in proper wash water treatment and a critical element in any wash water recycle system.

Consult Mi-T-M Corporation or your local distributor to determine the pit system configuration that works best for your application.