This freshwater reverse osmosis system efficiently removes contaminants with a multi pre-filter process and spiral wound membranes. It is customizable and can treat up to 2,000-gallons of water per day.

Benefits:

·Quality recycled water

·Removes 98% of dissolved salts and contaminants

·Easy operation and maintenance

·Multi pre-filter process with anti-scale, acid, alkaline cleaning and carbon filter options

·Anti-bacterial treatment

·Handles water between 50-100°F

·Treats up to 2,000-gallons of water per day

Features:

·Powder coated steel frame

·PLC controls for automated operation

·Low feed pressure shutdown

·ETL listed control panel

·Multiple spiral wound membranes

·Sediment pre-filter system with customizable filer options

Certification:

·ETL Certified – US and Canada

Recommended Applications:

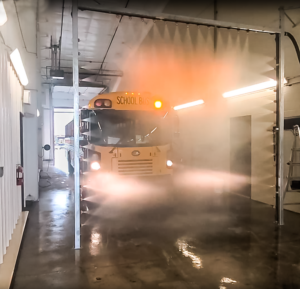

·Rental Yards

·Golf Courses

·Heavy Equipment Dealers

·Trucking Facilities

·Military Bases

·Truck Rental Fleets

·Diesel Repair Facilities

·Forklift Washing Operations

·Aircraft Maintenance and Restoration

·Shipyards

·Municipalities/State DOTs

·Oil Fields

·Engine Rebuilders and Manufacturers

Custom built units are available. Consult dealer for more information.

The Importance of a Proper Pit System:

Once equipment is washed, the untreated wash water flows into your pit system. A proper pit system for your application is the first step in proper wash water treatment and a critical element in any wash water recycle system.

Consult Mi-T-M Corporation or your local distributor to determine the pit system configuration that works best for your application.